Our products have passed CE, GS, EURO II, EPA certification, and our company is also certified with ISO9001-2000 standards.

Materials Check

Rockwell Hardness Tester

Test materials and parts with hardness over 20 degrees, such as crankcase, clutch, sprocket, etc.

Vickers Hardness Tester

Test materials with hardness below 20 degrees, such as pistons, cylinders, engine housing, aluminum products, etc.

Thermistor thermometer

Check temperatures of cylinders of chainsaws and brush cutters, to avoid over-heating and engine stall.

Run-out Tester

Check the stray value of crankshaft. A high stray value could lead to abrasion of oil seal and air leakage of cylinder which incurs failure starting of engine.

Pneumatic Measuring Instrument

Check if the cylinder bores are with proper values. A smaller bore may cause piston scraping; and a bigger bore may cause air leakage.

Magneto Test Stand

Check the flywheels to insure the ignition works normally. The ignition enables spark plug to continuously ignite while the speed is at 800 rpm during the startup.

Assembling Inspection

Air-tightness Check

Air-leakage check is carried out on engine parts during the assembling procedure.

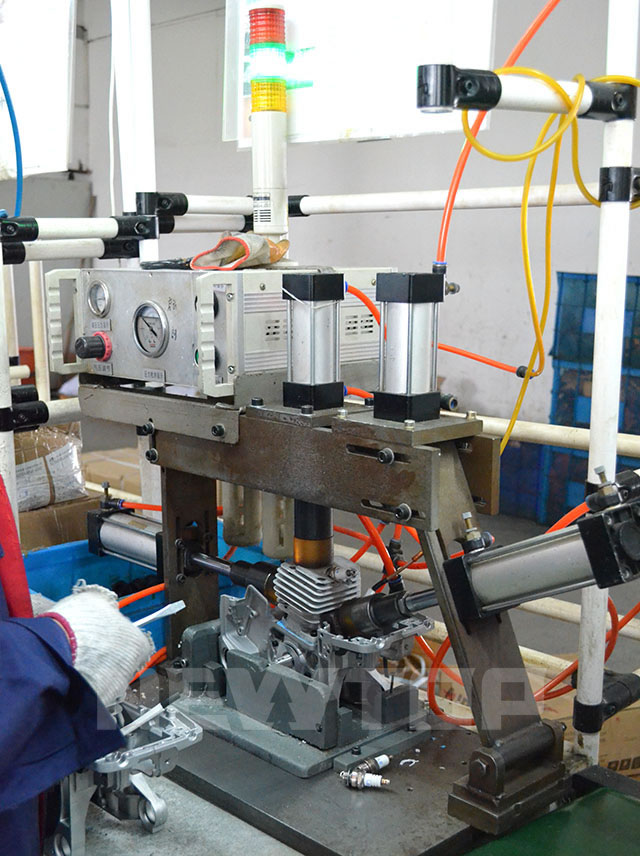

Assembling Technique

We have a highly skilled assembling team, which ensures the products we assemble are 100% qualified.

Adjustment & Troubleshoot

Adjustment & Troubleshoot

After being assembled, every machine must go through adjustment and troubleshoot to make sure our customers receive products without quality problems.